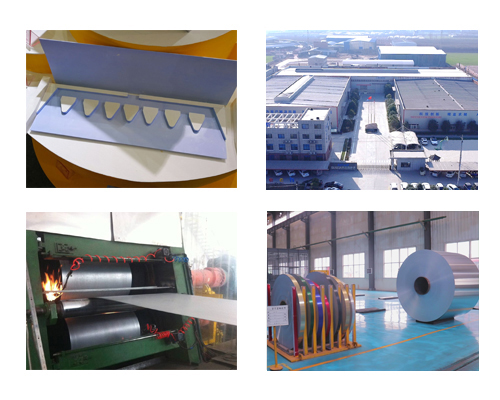

Double Zero Foil Process

The production process of double zero foil casting and rolling is: electrolytic aluminum liquid + solid waste smelting → standing → refining → online refining and filtering → online refinement → casting and rolling. The use of cast-rolled blanks shortens the process flow and avoids milling, preheating and hot-rolling procedures ...

Read More

Read More

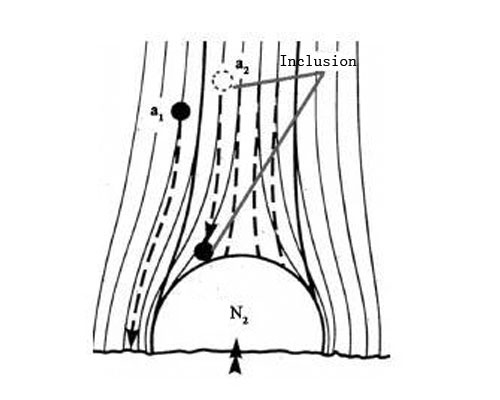

Metal Melt Refining

Most of the casting and rolling manufacturers use high-purity argon or nitrogen as the carrier for refining, and purify the melt by blowing fluxes into the metal melt for refining. Because the inert gas is insoluble in aluminum, when the uniform and small inert gas bubbles are blown into the ...

Read More

Read More

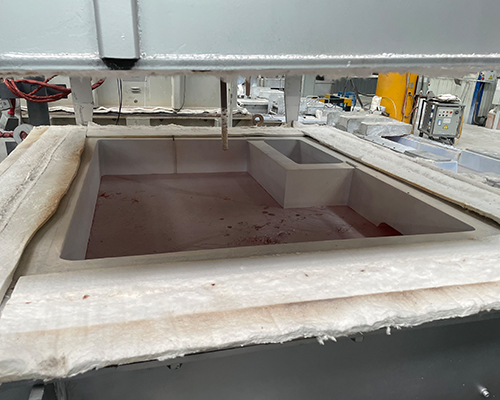

Online Degassing Purification

The purity of aluminum melt is one of the main factors that affect the pass rate of aluminum foil. The slag inclusions in the aluminum melt are not cleanly handled, which not only causes pores and embrittlement, but also accelerates the corrosion and causes the strip to break when the ...

Read More

Read More

Deep Bed Device

At present, the most widely used ceramic plate filter device, but its independent application in high-end products has greater limitations. Generally, ceramic plate filter device need to be matched with other filter devices, such as deep bed or tubular filter device. Tubular and deep-bed filtration devices are widely used in ...

Read More

Read More

Cast-Rolled Aluminum Strip

The quality of cast-rolled aluminum strip is generally related to the processing accuracy, configuration, and quality of auxiliary materials of the equipment itself. It mainly depends on the grinding process of the cast roll, the size of the roll gap, the lubrication of the roll surface, the casting temperature (the ...

Read More

Read More

Rotary Degasser Unit

Argon gas (containing a small amount of chlorine gas) is introduced into the online rotary degasser unit to remove the gas in the melt. The aluminum melt is sequentially filtered through a ceramic filter and a deep bed filter to remove non-metallic solid inclusions in the melt. Rotary nozzle inert ...

Read More

Read More

Fluxes for Purifying Aluminium

Impurity removal by fluxes is an important method for purifying aluminium melt. At present, there are many types of fluxes developed and used at home and abroad. In addition to the fluxes whose main purpose is to remove gas and impurities, there are also some other fluxes, such as covering ...

Read More

Read More

Fluxes for Aluminium Melting

Fluxes for Aluminium Melting can remove hydrogen, oxides, and other impurities. According to different uses, Fluxes for Aluminium Melting can be divided into refining agent, covering agent, slagging agent, cleaning agent, degassing agent, etc. Hydrogen, found in the foundry primarily due to the decomposition of water vapor, is very soluble ...

Read More

Read More

Gas Purification for Aluminum

Gas purifier purification refers to the introduction of gas into the aluminum melt or the substances that can produce purified gas. The partial pressure difference between the hydrogen in the aluminum melt and the bubble is used to make it diffuse into the bubble, and the bubble captures the inclusion ...

Read More

Read More

Fluxes for Aluminium Refining

Fluxes for Aluminium Refining are used to modify the aluminum alloy structure to improve cast product specific properties, such as tensile strength, elongation, machinability, dispersion of porosity, improved pressure tightness, and prevention of hot tears, depending on chemistry and alloy type. In addition, refining fluxes reduce hydrogen content and assist ...

Read More

Read More