ZrO2 ceramic foam filter with high properties was prepared by the process of organic foam impregnation. The method employed ZrO2 powders as raw material, Al2O3 and Y2O3 powders as a sintering aid. The influence of firing temperature and holding time on bulk density, thermal shock resistance, and compressive strength of samples was studied. ZrO2 ceramic foam filter was characterized by means of the tensile testing machine, integrated thermal analyzers, X-ray diffraction, and SEM. The experimental results indicated that the properties of as-prepared samples were best when the firing temperature was 1580℃ and the holding time was 120min. Samples were 0.452 g/cm3 in bulk density, 12 times in thermal shock resistance, and 1.56 MPa in compressive strength.

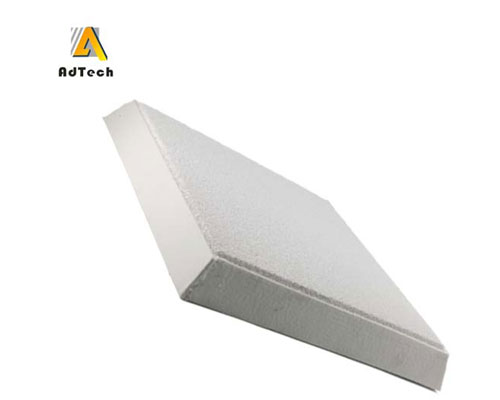

ZrO2 Ceramic Foam Filter

Foam ceramics is a 3D mesh skeleton structure with opening high porosity. Zirconia ceramic foam filter has a large filtering area, high filtration efficiency, good thermal stability, impact resistance to metal ability. It can be as the filter, catalyst carrier, sound-absorbing insulation cloth material, biological material. Foam ceramics are widely used in energy-saving, environmental protection, food, oil, refining, pharmaceutical, biomedical and other fields. But the current foam ceramics are widespread problems such as low strength, porosity easily blocked. ZrO2 has a molten high boiling point, high hardness, low thermal conductivity, good thermal stability, and high temperature creep characteristics. In addition, the martensite phase transformation of ZrO2, can rise to phase transformation toughening, microcrack toughening and dispersion toughening effect, which can greatly improve the toughness and strength of ceramics. Introducing ZrO2 material excellent performance of foam ceramics, to increase the toughness and strength of foam ceramics.

The Ceramic Foam Filter-PZr adopts the high-performance organic foam impregnation process. It has a good sample neat degree, porosity inter-permeation, skeleton structure for 3D mesh structure. Use automatic extrusion equipment to make the slurry evenly distributed in the foam skeleton.