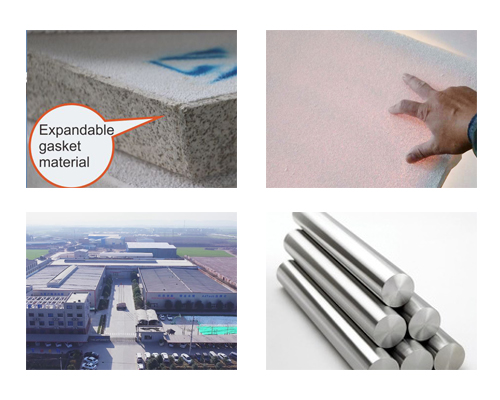

Foam Ceramic Filter is used in the aluminum metallurgy industry and aluminum rod and ingot foundries to remove non-metallic inclusions and metal fusion in molten aluminum.

Non-metallic inclusions in castings are the most important cause of casting defects. Casting defects will affect the surface finish, mechanical properties and processing properties of the castings, and will increase the rejection rate. Although most of the slag inclusions are removed from the aluminum melt during refining, some fine slag particles, especially those below a few microns, are difficult to remove by furnace refining and online refining, and they are still suspended in the aluminum melt. Strict filtration treatment is required before casting and rolling. Let the aluminum melt pass through the ceramic foam filter medium, so that the impurity particles in the melt are intercepted by the surface of the filter medium, so as to achieve the purpose of purifying the aluminum melt.

Alumina ceramic foam filter products are designed to remove inclusions and reduce turbulence, so as to achieve a rapid and stable flow of molten metal, thereby improving the quality of castings.

It has excellent filtering effect on all aluminum and aluminum alloys.

Advantages of Aluminum Foundries Ceramic Filter

1. Adopt the principle of adsorption, which can effectively remove large inclusions in molten aluminum and effectively adsorb small inclusions;

2. No slag drop, effectively reducing the pollution of molten aluminum;

3. Good thermal shock resistance and good resistance to molten metal corrosion;

4. Automatic assembly line production, three calibration procedures, accurate size, more in line with the filter box;

5. Improve surface quality, product performance, and microstructure.

Foam ceramic filter plates are widely used all over the world because of their convenient use, good filtering effect, and low price. Aluminum alloy melts are filtered by foam ceramic filter plates, which are generally 50mm thick, 200-600mm long and wide, and have a porosity of 80% to 90%.