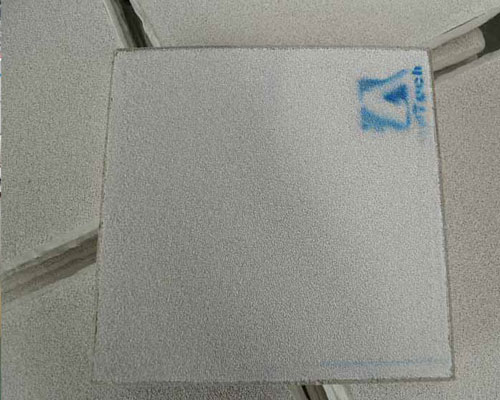

Molten aluminum foam ceramic filter is made of an open-cell hydrophilic flexible foam material with a plurality of interconnected voids surrounded by a net of flexible foam material. Typical materials that can be used include polymer foams, such as polyurethane foams, and cellulose foams. Generally, any combustible organic plastic foam that has elasticity and the ability to restore its original shape can be used. The foam must be burned or volatilized below the firing temperature of the ceramic material. Likewise, a foam material with 5 to 100 pores per inch should be used to provide the necessary filtering surface. Of course, the size of the foam material can vary according to the desired size of the end filter material. Generally, the thickness of the foam material used is 1/4 to 4 inches, preferably 1 to 3 inches.

The aqueous ceramic slurry used depends on the desired ceramic material of the selected metal to be filtered. A structure that must have sufficient properties in the final product to resist specific molten metal chemical attack and specific high temperature conditions. In addition, the slurry should have high fluidity and consist of an aqueous suspension of the ceramic intended for the filter. Typical ceramic materials that can be used include aluminum oxide, chromium oxide, zirconium oxide, magnesium oxide, titanium dioxide, silicon dioxide, and mixtures thereof.

An aqueous ceramic slurry with ceramic fiber additives is prepared and the foam material is impregnated with the foam material to coat the fiber web with it and substantially fill the voids with it. Then, compress the impregnated material by squeezing through a preset roll, so that about 80% of the slurry is preferably discharged, and the balance is evenly distributed throughout the foam material, so that some holes are evenly distributed to block Increase the twists and turns. The coated foam material is then dried and heated to first burn off the flexible organic foam, and then sinter the ceramic coating to provide a molten ceramic foam with a plurality of interconnected voids surrounded by a bonded or molten ceramic mesh, And it is foamy. The ceramic fibers protrude from the walls of the molten ceramic, thereby providing a fuzzy surface on the pores of the ceramic foam filter, which tends to increase filtration efficiency.

Molten aluminum foam ceramic filter is high-efficiency ceramic foam material for filtering molten metal, especially molten aluminum. The ceramic foam material is characterized by having an open-cell structure, a plurality of interconnected voids surrounded by a ceramic fiber mesh.