Ceramic filter for aluminium foundry is commonly used to filter various molten aluminum.

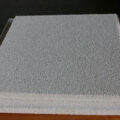

Ceramic filter for aluminium foundry formed by impregnating organic foam with an aqueous slurry, the slurry composition containing 20%-50% silicon carbide, 20-50% alumina, 1.5-5.0% aluminosilicate fibers, And it has been fired at a temperature of at least 1150°C so that the filter has a ceramic matrix in which substantially all aluminosilicate fibers are dissolved.

The ceramic foam filter can be manufactured using a known method of manufacturing ceramic foam, in which organic foam (usually polyurethane foam) is immersed in an aqueous slurry of ceramic material containing a binder, and the impregnated foam is dried to remove water And dry. Burn the impregnated foam to burn off the organic foam to produce ceramic foam.

A method of manufacturing ceramic foam filter, the method includes forming an aqueous slurry containing silicon carbide, alumina, colloidal silica sol and aluminosilicate fibers, immersing organic foam in the slurry, and drying. The foam is impregnated to remove water and the dry impregnated foam is fired at a temperature of at least 1150°C.

When the filter is fired, the fine particles of colloidal silica, aluminosilicate fibers, and alumina interact to form a ceramic matrix that surrounds the silicon carbide and coarser alumina particles and has a main binder phase of aluminum silicate. The massive dissolution of aluminosilicate fibers in the ceramic matrix can be demonstrated by microscopic examination of the ceramic foam filter using a scanning electron microscope (SEM).

The slurry may also contain other additives to improve the application performance of the slurry during the impregnation process of the organic foam. Examples of such additives are rheological agents such as clay, fumed silica or organic thickeners; coating aids such as polyvinyl alcohol and defoamers.

AdTech is a ceramic filter manufacturer with an automatic production line and three calibration procedures, which guarantees the high accuracy of product dimensions. Ceramic Foam Filter product specifications are 7 * 7in, 9 * 9in, 12 * 12in, 15 * 15in, 17 * 17in, 20 * 20in, 23 * 23in, 25 * 25in, 26 * 26in or customized according to the shape and size of customer needs. Ceramic foam filter Pore Size(PPI):10/20/30/40/50/60. If you need them, contact us – sales@alalloycasting.com.