The molten aluminum filtering process is a process of removing inclusions mainly including oxides and non-metallic substances in the filter. Common methods for filtering and……

The hot top casting method is widely used in the aluminum round rod casting process. In this way, not only can the contact conditions between……

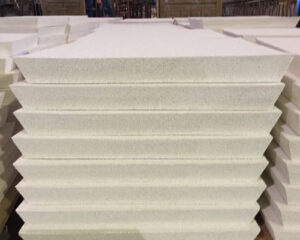

In the manufacturing process of the ceramic foam filters, the open-cell polyurethane foam board with appropriate pore size is completely immersed in the mud bath,……

The plate filter units can be sealed by gaskets around their edges. The plate filter unit is preferably sealed by an edge seal along the……

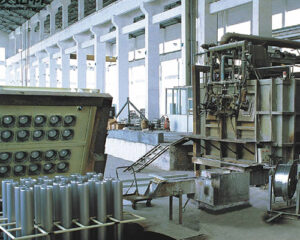

The degasser system uses the rotor in the stator to remove the gas from the molten aluminum. Molten aluminum degasser system usually uses one or……

The filter must be able to form a suitable geometric shape. In addition, the filter material must have unique strength and chemical resistance to filter……

Kyanite powder is used in the manufacture of ceramic foam filters, but any aluminosilicate, amorphous silica, magnesium aluminum silicate, or lithium aluminum silicate powder can……

Before the molten aluminum is solidified into an ingot or billet by filtration, it is best to remove the inclusions in the final processing step.……

Ceramic foam filters for aluminum casting filtration mechanism usually described as interception, sediment layer and deep filtration. Ceramic Foam Filters for Aluminum Casting 1. The……

The ceramic foam filter has been used to remove impurities in aluminum fluids for over 30 years. After successful use in industrial practice, it quickly……