As a well-known foam ceramic filter manufacturer, we can produce 20-60PPI ceramic filters to meet the needs of the aluminum metal casting process. Ceramic foam……

Furnace refining with flux is widely used in aluminum foundry. The main goal of aluminum melt purification technology is to continuously improve the purity of……

Aluminum and aluminum alloys are easy to inhale and form inclusions during the smelting and pouring process, which directly affects the quality of their products.……

For aluminum and aluminum alloys, degassing and slagging with flux is an important method. When using flux refining, a large number of dispersed and fine……

When using the fluxes for aluminum refining, the fluxes are pressed into the molten pool with a bell jar, and the volatile bubbles generated by……

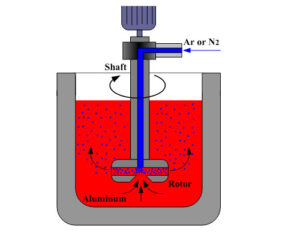

Inert gas metal refining is a refining method in which inert gas is continuously blown into the aluminum melt, and oxidized impurities and hydrogen are……

The main purpose of molten aluminum degassing refining is to remove the gas dissolved in the molten metal. In the process of heating and smelting……

According to the different degassing mechanisms, the molten metal degassing refining method of aluminum alloy melt can be divided into partial pressure difference degassing, compound……

Degassing flux is usually used to reduce the hydrogen content of the molten aluminum alloy. Reducing the hydrogen content will definitely improve the mechanical properties……

The cover flux prevents oxidation of the molten aluminum by providing a physical barrier. Cover flux will reduce the rate of hydrogen absorption from the……