The size of the gap in nozzle and roller has a great influence on the longitudinal streaks. In normal production, due to the assembly error……

The aluminum melt refining in furnace is carried out in two steps: The first step is pre-refining in the melting furnace. When the chemical composition……

During the casting process, aluminum melt online processing is necessary. The aluminum alloy melt flows through the online degassing device and the online filtering device……

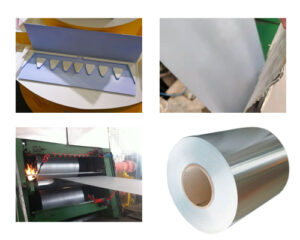

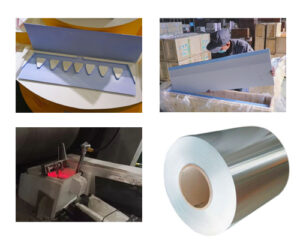

The casting tips and temperature of vacuum formed headbox are the key factors to ensure the aluminum coil casting and rolling production. After lowering the……

Choosing the right caster tip and nozzle material is important for aluminum sheet casting and rolling production. AdTech Caster Tip and Nozzle are used for……

Aluminum melt purification method adopts the bubble floatation method for three refinings, blowing N2+ high-temperature refining agent into the melt, and on-line purification outside the……

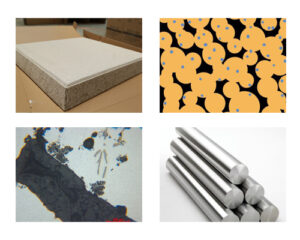

The inclusions in molten aluminum have a great impact on the use of aluminum plates, so the removal of inclusions must be strictly controlled during……

CFF (Ceramic Foam Filter) aluminum melt filtration can not only remove physical inclusions through surface interception and adsorption, but also has the effect of solvent……

Various melt refining technologies have continuously improved the quality of castings. One such process is the so-called ceramic foam filter for metal melt filtration, which……

In the production process of aluminum and aluminum alloy cast-rolled plates, the life of the casting tip nozzle directly affects the output and quality of……