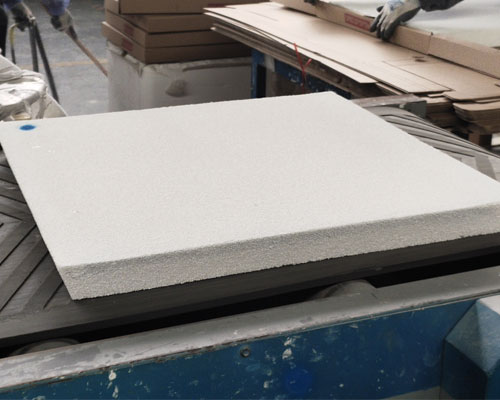

The alumina ceramic filter plate can effectively remove the large impurities in the aluminum liquid and adsorb the micron-level fine impurity particles, thereby improving the surface quality, improving the product performance, improving the microstructure and increasing the output. It is widely used in the production of aluminum profile, aluminum foil and aluminum alloy.

The use of alumina ceramic filter plates is mainly based on the following considerations.

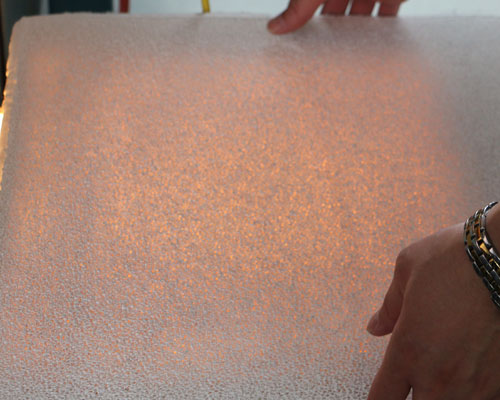

On the one hand, filtration makes the flow of molten aluminum orderly and relatively calm.

On the other hand, solid slag in molten metal is effectively removed, and casting quality is rapidly improved.

The alumina ceramic filter plate has excellent strength, high temperature impact resistance and chemical corrosion performance. It can withstand high temperatures up to about 1560°C. Ceramic foam filters can significantly improve the quality of cast iron parts and reduce the scrap rate. It can also be used in continuous casting and rolling processes, and can be manufactured in all standard sizes and different thicknesses. Both ordinary and special sizes required by customers can meet the requirements.

AdTech specially designed Ceramic Foam Filters are made of the basic raw material Aluminium Oxide. Alumina ceramic filters can effectively remove solid inclusions in molten metal. Therefore, aluminum alloy can be smoothly forged, aluminum foil manufacturing, extrusion processing, etc. to obtain perfect aluminum products. The coarse porosity of this product ranges from 10ppi to 60ppi, so there will always be a product standard that suits your requirements.

30ppi 40ppi ceramic foundry filter is the most commonly used ceramic foam filter in the aluminum casting industry. Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates. Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

Alumina Ceramic Filter Plate Features:

– A homogeneous pore structure

– High surface strength

– Temperature resistant up to 1100°C

– Excellent resistance against chemicals used in foundries