The casting tips and nozzle, vacuum-formed headbox and tundish are the key factors to ensure aluminum coil casting and rolling production. After lowering the vacuum-formed……

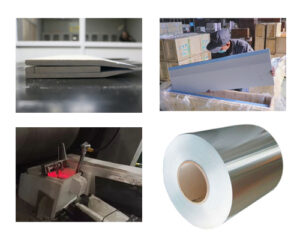

Metal continuous casting and rolling technology has developed rapidly since the 1970s and has been widely used in the aluminum industry. Metal continuous casting and……

Many enterprises use the electrolytic aluminum liquid as much as possible to directly put it into the melting furnace of casting and rolling, which saves……

The aluminum ingot produced by hot top casting has uniform structure and good mechanical properties. In order to obtain such a casting structure, aluminum ingot……

The aluminum hot top casting has the advantages of excellent internal and surface quality of the ingot and easy production and operation, so the hot-top……

When the casting speed and cooling water volume (water pressure) both reach the normal value of casting, Aluminum Ingot Casting Process begins to enter a……

Whether it is ordinary hot-top casting or advanced air-slip casting, the casting process of generally the same level of hot-top casting can be divided into……

Aluminum melting refining flux is powdery particles, which are passed to the bottom of the pool through a refining device, so that there are a……

Refined Powder Fluxes are used as a refining agent for degassing and slagging of aluminum metal in the aluminum alloy casting process. AdTech’s refining agent……

The AdTech granular refining fluxes are smokeless, tasteless, dustless, easy to operate, and have a good degassing effect. It is a special refined dust collector……