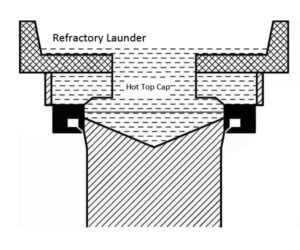

Ordinary hot top casting technology is to place a bottomless light-weight insulation material storage tank connected with the launder at the upper end of the……

Aluminum silicate refractory fiber products can be directly used as a filling material for high temperature insulation, but the most commonly used are various refractory……

With its unique properties, aluminum foil meets various needs of modern production in a wide range of fields. With the development of economy and technology,……

In the industry, molten aluminum purification methods such as flux purification and gas purification are mainly used, and some try tube filters, ceramic foam filters,……

The aluminum liquid degassing device achieves the purpose of stable operation by changing the rotor power transmission mode, making it possible for the rotor to……

There are many rotary degassing purification equipment, usually set between the discharge port of the furnace and the filter box. The degassing principle is: high-temperature……

Ceramic foam molten aluminum filtration technology has been used to remove inclusions in molten aluminum for more than 30 years. After the foam ceramic filter……

The principle of the online degassing system for aluminium is that the solubility of hydrogen in aluminum is determined by the partial pressure of hydrogen……

Before casting, continuous casting, and other uses, molten metals containing small amounts of dissolved, particulate and gaseous impurities (such as aluminum and aluminum alloys) are……

Years of casting experience show that proper flux for aluminum casting is a key factor to reduce costs and improve the quality of liquid melt.……