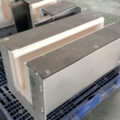

Refractory Casting Launder is one of the Refractories primary product offerings from our fabrication department. Our high-quality refractory casting launder has been provided to both aluminum industry customers and the non-ferrous market. We have experience producing a large variety of different shapes for our customers in different industries. We can often provide insight into causes of premature launder failures and offer material or design change recommendations to correct the problems. Christy Refractories offers a complete line of castables to choose from our in-house castline. Christy has experience casting most major manufacturers’ castables. We have provided customers with precast refractory launder relines, as well as designed and built entirely new custom launder systems.

Precast refractory launders come in a number of shapes and sizes depending upon the industry. They can also be referred to as troughs, runners, or a number of other industry names. They run the gamut from very simple drop in place relines to custom precast pieces in Y or T configurations with seats for flow control components. Particularly challenging for the refractories are surge bowls and runners. This is where the refractory sees the greatest metal velocity and abrasion loss. Christy offers a number of proven solutions to ensure the longest service life in these areas. Please contact sales@alalloycasting.com, our sales and application engineering teams for more information specific to your application.

The most technically advanced way to deliver molten aluminum from melting furnaces to holders and die casting machines is in a heated launder system. A launder minimizes turbulence and oxides in the molten metal. And, because the metal flows in a quiet stream to the holding furnace, it eliminates transfer labor and monorails, fork trucks and bull ladles. It automatically delivers the exact amount of metal you need – on-time and at temperature. Launder systems aren’t the answer for everyone. They must be carefully considered because they can reduce the flexibility of your plant layout. But they can be very cost-effective in the right application. We have both the technology and the creative designs to meet your needs. Our refractory casting launder is well sealed, highly insulated and easy to clean.

Refractory Casting Launder

Adtech recently installed over 300 feet of launder at one of the most modern aluminum foundries in the U.S. to serve an array of melting, holding and filtration/degassing furnaces. Another 270 foot launder serves six vertical die casting machines and three central melt furnaces and another runs 110 feet from a filter furnace to the first 10 of what will be 24 interconnected holding furnaces when the installation is complete.

Metal quality – ensured through minimized turbulence and oxides.

Highly insulated – to maintain temperature.

Easy to clean.

Reduces the need for transfer equipment.

Reduces manpower and fork lift maintenance.

Save of 1% in metal melt loss caused by turbulent transfers into and from transfer ladles.

This versatile launder system meets the needs of a variety of metal casters, high and low pressure die casters, and permanent mold, sand, investment and lost foam foundries around the world.