Refractory launder is mainly used for molten metal transfers from the melting furnace to the casting machine. If the launders are not covered and heated, the metal cools when it travels the long launder line. Because casting machines require metal at a specific temperature, the furnace’s operating temperature relates to the launder line’s thermal efficiency. Therefore, the thermally efficient casting launder line allows a lower operating temperature in the furnace, results in energy savings, and reduces hydrogen in the molten aluminum.

When launders are not fully preheated, the molten metal absorbs heat until the launder line reaches equilibrium. The preheat temperature and the thermal efficiency of the launder line affect the amount of metal lost each casting, and the time required before the system reaches equilibrium.

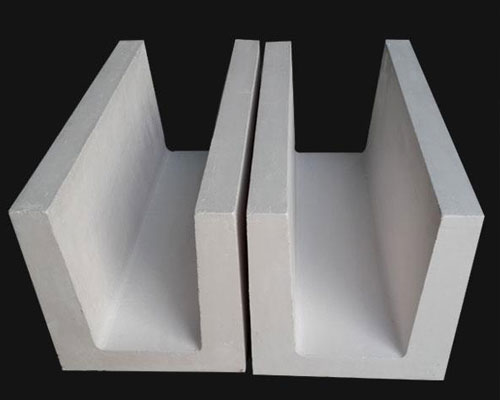

Refractory Launder

The metal going into the casting machine must be free of “inclusions”. The quality of the launders can affect the risk of refractory pieces. For several years, Adtech has fabricated high-quality casting launders. Adtech has developed forming and casting techniques with much time and energy and produces refractory launders with an unparalleled quality of surface finish.

Further, Adtech’s specialized forming techniques reduce stresses on the launders during deforming. This reduces micro-crack occurrence and retains the maximum mechanical and thermal shock resistance. Adtech casts launders in several different materials depending on the specific operating conditions.

Adtech Engineering Department has developed a system of non-steady state heat transfer calculations. This system permits its model and optimizes the thermal performance of casting lines based on different refractory, insulation, and pre-heat configurations. They can also design the launder geometry to specific flow rate, maximum velocity, and time of retention criteria.

Adtech can provide high-performance casting line launders, and complete casting line launder solutions, adapt specifically to client needs.

Pingback:Launder Transfer System – 站点标题