The molten metal launder is a key component in the large aluminum alloy die casting production line. This is the channel to ensure that the high-temperature aluminum liquid smoothly enters the pressure chamber. Smooth transfer is the key to melt quality, because any turbulence will cause oxides in the molten aluminum. The launder system can eliminate any kind of agitation at every step.

The molten aluminum launder can maintain the heat of the molten aluminum and save energy. Gentle heating, pneumatic sink cover, tightly sealed, strict temperature control and clever fire-resistant design features. These can keep the aluminum melt at the optimal temperature, eliminate heat loss, and use the metal’s own thermal conductivity to reduce energy costs.

Molten Metal Launder Advantage

- Metal quality-ensured by minimizing turbulence and oxides.

- Highly insulated-maintain temperature.

- Easy to clean.

- Reduce the demand for transmission equipment.

- Reduce manpower and forklift maintenance.

- Save metal melt loss caused by turbulence in and out of the ladle.

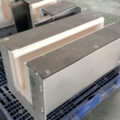

The launder system is completely fireproof when it leaves the factory and has been pre-installed mechanically and electrically. According to the layout design, each element is sealed and bolted together. Then, fill a small amount of refractory material at the joint to optimize the insulation effect. There is no risk of leakage.

The casting launder eliminates equipment and labor costs, as well as the inherent hazards associated with transferring molten aluminum from the melting furnace to three holding furnaces with forklifts and transfer ladles. The casting launder also maintains the molten aluminum at the set point temperature until it reaches the holding furnace, which means that no temperature is lost during the transfer.

Overall, the casting launder system saves energy by eliminating two pourings. From the melting furnace to the conveying ladle, and the other from the conveying ladle to the holding furnace. It eliminates the oxides and hard spots that are formed every time the molten aluminum is disturbed, which is very effective for customers and improves the safety of workers.