In most molten metal processes, metal transfer is a critical step because it affects metal quality, productivity, waste volume, and overall safety.

The transfer of molten metal may occur when casting ladles, transferring between furnaces, transporting casting lines, and filling ingots and master mold lines.

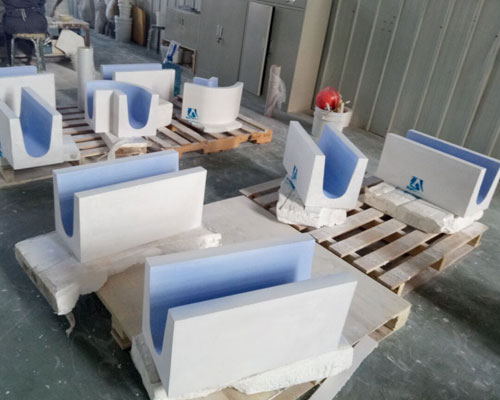

In order to improve the overall performance and reliability of metal transfer, Adtech provides an improved molten metal transfer launder, which will improve metal quality through static flow, improve flow control, generate more lift, reduce transfer time, reduce cost and waste, and improve operator safety.

The static flow improves the metal quality, eliminates the metal surge generated by the downstream process, and ensures the integrity of the ceramic foam filter / degassing process. It pulls the metal from the middle of the bath to obtain the best metal quality, rather than from the top or bottom. There is no need to tilt the furnace or stop other processes such as melting and alloying.

The most advanced technology for transporting molten aluminum from the furnace to the support and die casting machine is in a heated washing system. The sink minimizes turbulence and oxides in the molten metal. Moreover, since the metal flows to the holding furnace in a quiet manner, the transfer of labor is eliminated. It can automatically supply the required amount of metal according to the temperature on time. Washing systems are not everyone’s answer. They must be carefully considered because they reduce the flexibility of the plant layout. But in the right application, they can be very cost-effective. We have technology and creative design to meet your needs. Our sink is well sealed, highly insulated and easy to clean.

AdTech casting launder adopts advanced technology to produce metal transfer lining, greatly improve the erosion resistance. It can effectively prolong the service life of the launder’s lining. To match with our BN coating, it is good non-sticky aluminum performance. The lining could be produced separately as the customer’s requirements.