In conventional casting systems, a metal launder typically has a plurality of metal discharge spouts, and spans a like number of casting stations. It is generally impractical to provide external vertical support for the launder at any intermediate positions along its length. Rather, the launder is supported at both of its ends, and is designed with sufficient structural strength to support its own weight and the weight of any molten aluminum contained therein.

However, a metal level sensing system not only that a launder be strong enough to support itself, but that it be strong enough to establish and maintain a stable measurement platform from which molten metal level measurements can be made.

Molten metal level is thus controlled and maintained relative to the elevation of the metal distribution launder. Any change in the elevation of the launder will cause a corresponding change in the level of molten aluminum within an underlying casting station. It is, therefore, extremely desirable to provide a metal distribution launder that resists movement or flexure in the vertical direction.

Vertical launder flexure results from two causes: variability in the amount and corresponding weight of contained molten aluminum, and vertical temperature gradients produced in structural parts of the metal distribution launder. Flexure from the first cause can be reduced by providing structural reinforcement along the length of the metal distribution launder. However, structural reinforcement is not effective against heat-induced launder flexure.

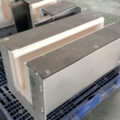

A low-flexure molten metal distribution launder comprises an elongated structural beam that extends over a plurality of casting stations. A plurality of metal level sensors extend downward from the elongated structural beam to measure molten metal levels in underlying metal casting stations. A plurality of spaced U-shaped refractory hangers are supported within the structural beam to form a refractory channel.

Refractory liners are received within the refractory hangers to form a molten metal trough within the structural beam. The hangers are spaced from each other and supported from the structural beam in such a way as to allow them to expand and contract relative to the structural beam without subjecting the structural beam to expansion and contraction. The walls of the refractory hangers are air-cooled to reduce heat transfer from the refractory hangers to the structural beam.