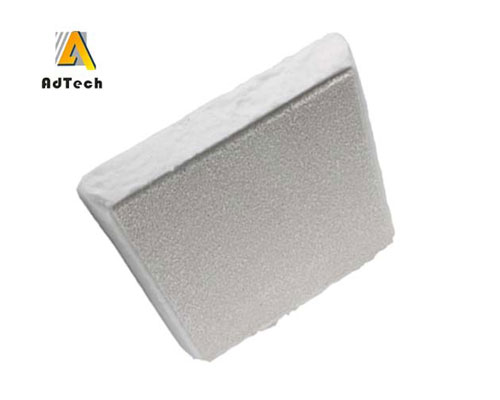

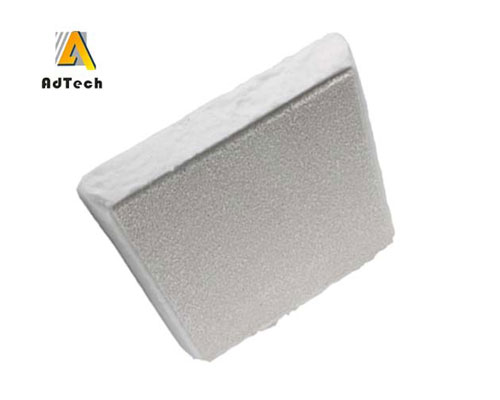

Ceramic Foam Filter With Fiber Blanket Sides

It’s very important to choose and design Ceramic Foam Filter model & filter seat correctly according to casting types and pouring weight. The general principle is that the whole gating system should be a system without pressure to ensure that the molten metal liquid filling mould smoothly. The ratio of the sectional area will be the main point.

Advantages of Ceramic Foam Filter With Fiber

Increased Fluidity

Removal of inclusions makes the metal more fluid, resulting in easier mold fill, better cast structure, and better thin section castability.

Ceramic Foam Filter :

1.Expandable Gasket Sealing

2.Fiber Cotton Sealing

3.Fiber Paper Sealing

A sealing gasket is applied around the ceramic filter plate to act on the contact surface of the filter plate and the filter box to prevent leakage of the aluminum liquid through the contact surface. Our filter plates are made of 3 types of sealing gaskets including fiber paper sealing;fiber cotton sealing;expandable gasket sealing.

AdTech alumina foam ceramic filter plates use organic foam as a carrier. These organic foams have a three-dimensional network structure. Put the foam carrier into a special ceramic slurry with thixotropy. Then, technicians use a special roller extrusion process to uniformly coat the ceramic slurry on the carrier. After drying and curing, the final ceramic filter plate is fired at high temperature. There is a sealing lining around the ceramic filter plate. It is mainly used for the contact surface between the filter plate and the filter box to prevent liquid aluminum from leaking through the contact surface.

The ceramic foam filter can make the aluminum water fill the cavity more evenly. Molten metal has a higher tendency to turbulence during casting. Liquid aluminum is passed through the three-dimensional pore structure of the zirconia foam ceramic filter and finally transformed into a very stable laminar flow. Laminar flow can better fill the cavity, thereby reducing the impact corrosion of molten metal to the cavity. If you are interested in our products, please feel free to contact us.