Foam Furnace Filter plays an important role in filtering inclusions in molten metal. The casting defects of slag greatly affect the production efficiency and economic benefits of metal foundries. The large inclusions on the surface of the casting reduce the smoothness of the surface, and in severe cases, it directly leads to the scrap of the casting. Inclusion defects are usually found only in the processing stage and the actual use stage. During processing, the use of scrap castings usually leads to higher losses because of the previous multi-pass operation.

Metal inclusions can be divided into two categories according to their sources. Foreign inclusions come from furnace lining, ladle refractory corrosion, slag, or react with air to form scum or other inclusions. Another type of inclusion is endogenous inclusion. Such inclusions are formed by the reaction of molten metal.

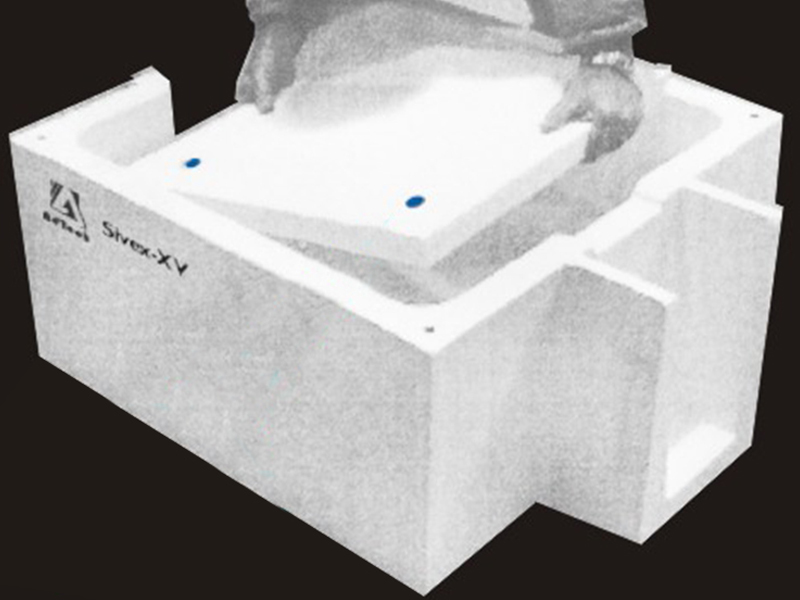

Foam Furnace Filter tends to filter out small inclusions. Most of the filtered inclusions are located at the inlet of the straight hole filter. On the other hand, the ceramic foam filter has inclusions that are stranded at the depth of the filter. Inclusions whose surface is smaller than the opening size will pass through the filter and be trapped on the filter surface. Reticulated ceramic foam filters usually play an important role in reducing turbulence in the gating system. This will greatly reduce the re-oxidation of the molten metal, thereby reducing the formation of slag.

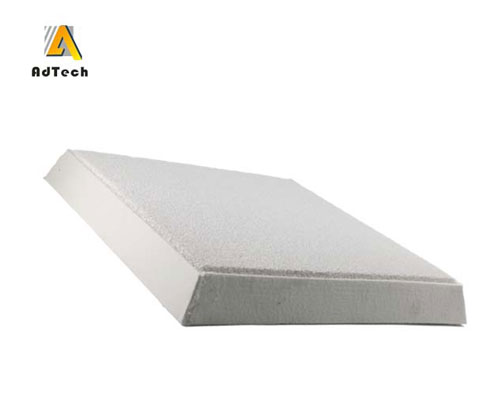

The Ceramic Foam Filter must be as close as possible to the casting in order to obtain the maximum filtration efficiency and adjust the flow rate. The greater the strength of the thickness of the filter, the better the strength of the filter, and the higher the filtration efficiency. Of course, the use cost is also higher. The filters have various sizes and thicknesses to meet the different needs of users.

Inclusions are one of the main casting defects in casting. It not only affects the surface quality of the casting, but also reduces the performance of the casting. Inclusions also increase the processing difficulty. Inclusions appearing after processing not only cause casting waste, but also increase processing costs. Inclusions are also an important cause of porosity defects in castings. AdTech offers Open Cell Foam Filter Material for filtering molten metal. If you are interested in our product, please contact us anytime.