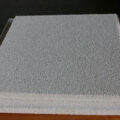

Molten aluminium foam ceramic filter has ceramic foam in the form of a honeycomb structure, and the ceramic foam filter is generally used to filter molten metal before casting.

AdTech provides a molten aluminium foam ceramic filter whose peripheral surface is surrounded by a gasket made of fiber material. AdTech filter adopts sealing gasket in 3 different types, fiber paper material, fiber cotton material, expanding cotton material.

AdTech ceramic foam filter plates are produced on the basis of a carrier with a solid network structure and organic foam cells. The production steps are as follows. The carrier is put into the thixotropic alumina slurry, and the square centering automatic extrusion process is adopted to make the slurry uniformly deposit on the foam skeleton of the carrier. After drying and solidification, the carrier is formed by baking and finally becomes the final product.

The horizontal cross-section of the ceramic filter can be any desired shape, but will generally be round, square or rectangular.

The gasket may be made of a soft, flexible strip of ceramic fiber material, which is preferably free of organic compounds, thereby avoiding the possibility of metal absorbing hydrogen when filtering metals such as aluminum. The thickness of the strip is usually 3 to 6 mm, and the strip can be compressed to 1 to 2 mm. The width of the gasket may be the same as or smaller than the thickness of the filter.

The gasket of the filter enables the filter to be fixed and sealed to the metal filter device, thereby avoiding the movement of the filter during filtration. It can prevent the fiber from being lost from the gasket during transportation, handling or use.

In order to manufacture aluminum products with acceptable characteristics, such as beverage cans and aircraft fuselage parts, aluminum must be substantially free of inclusions and defects. When aluminum melts at the beginning of the casting process, it becomes full of oxides, borides, salts, and other impurities, which may eventually appear as harmful inclusions in the final product. It is desirable to remove these inclusions before curing the aluminum. This is usually achieved by passing molten aluminum through a ceramic foam filter.