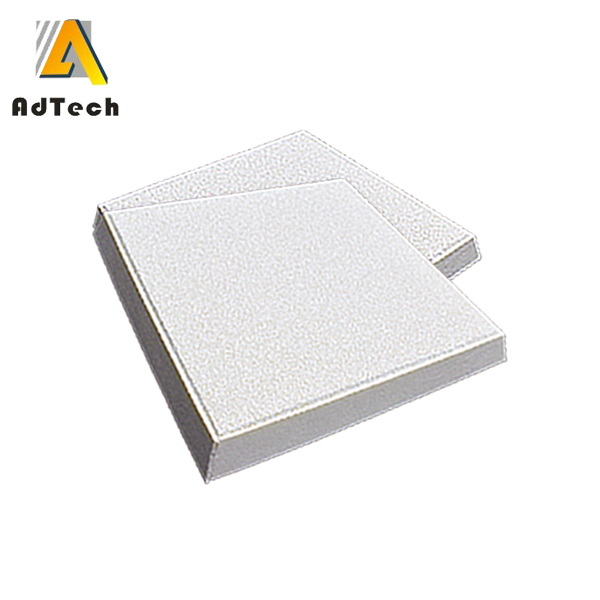

1. Pottery-based working principle

The appearance of the porous ceramic filter and the mechanism-controlled vacuum filter machine work principle is similar, under the immediate pressure differential action, when the suspended liquid passes through, the surface formation of the suspended particles, and the fluid passes and the suspended particles flow out. , Achieved the purpose of solid-liquid separation, there is a difference between the material in the filter-ceramic filter plate tool produced by the micropores, the micropores in the micropores of the micropores, the force of the micropores, and the force applied by the vacuum, the use of the micropores at the beginning and end to hold the filling liquid Under no circumstances, the ceramic filter plate does not allow air to pass through, because there is no air permeation, the solid-liquid separation time consumption is low, the vacuum level is high, the main components of the ceramic filter, the stirrer, the knife assembly, the material Composed of tank, distributor, ceramic filter plate, vacuum system, cleaning system, and automated control system.

2.porous ceramic filter technology performance and technical advantages:

Ceramics filtration machine is a new type, of high-performance, high-performance solid-liquid separation equipment, launched in the 1980s. excess. Due to the difference in solid-liquid separation equipment and other solid-liquid separation equipment, the material is caused by the ceramic filter plate, which has micropores, and the micropores in the micropores have a large force applied to the vacuum, and the microscopic force is applied. At the beginning of the hole, it retains the liquid state and is impermeable under no theory, and the degree of vacuum is high, and its main features are:

1, general vacuum is between -0.095-0.098MPa, low moisture content, high output;

2、Vacuum loss, Written by Xiano;

3. The micropores of the ceramic sheet are generally 0.5-2um left and right.

4. High degree of equipment automation, low mechanical strength, simple operation, and small workload.