Porous ceramic filter product has high porosity, excellent filtering effect, low-pressure loss during the filtration process, high filtration efficiency, and long service life. the porosity……

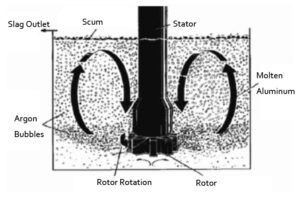

Rotating Degassing method is currently the most widely used method of degassing and purifying molten aluminum. The principle of rotating degassing is to pass an……

Aluminum oxide ceramics is a ceramic material with alumina (Al2O3) as the main body, used for thick film integrated circuits. Alumina ceramics have good conductivity,……

Zirconium Oxide Ceramic also called zirconia ceramics. Zirconia Ceramic has high melting and boiling points, high hardness, insulators at room temperature, and electrical conductivity at……

In the melting and casting production of deformed aluminum alloys, hot top casting is a widely used casting process, which has the following characteristics: (1)……

The main problem of Sr modification is the increasing tendency of micropore formation in the alloy. The effects of melt filtration and Sr modifier on……

There are many factors that affect the quality of aluminum and its alloys. Among them, the hydrogen content, inclusions and alkali metal concentration of molten……

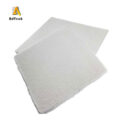

CFF Filter System mainly includes ceramic foam filter. Alumina Ceramic Foam Filters mainly for filtration of aluminum and alloys in foundries and cast houses. To……

Porous Ceramic Filters Manufacturing Process is made of silicon carbide only, with the exception of a small number of oxides in the form of adhesive……

CFF for Foundry is a high quality filter used in molten aluminum, copper based alloys and ferrous metals (including gray alloys, ductile alloys and steel……