Aluminium Sand Casting

Aluminium Sand Casting is a casting method in which casting sand and core sand are used as molding materials, and liquid metal is filled under gravity to produce the casting. Aluminum, iron, and most non-ferrous alloy castings can be obtained by sand casting. Because the molding materials used in sand ...

Read More

Read More

Permanent Mold Casting

Permanent mold casting is also called hard mold casting. The casting mold is made of metal materials, such as cast iron, carbon steel or low alloy steel. Under the action of gravity, the molten metal fills the metal mold cavity and is cooled to form a casting. Permanent casting can ...

Read More

Read More

Drossing Flux for Aluminum

Drossing flux for aluminum is used to remove impurities in aluminum water during casting. The main raw material of the slag removing agent is volcanic ash minerals, the main component is silicate. Deslagging agent is formed through special processing and proportioning, and is mainly used for slag removing and heat ...

Read More

Read More

Refractory Products

Refractory materials are the basic materials for high-temperature industries. The application fields of refractory products include steel industry, cement industry, non-ferrous metal smelting process and glass industry. What Is Refractory Products? Refractories, according to international standards, refer to non-metallic materials whose chemical and physical properties are stable, and use in ...

Read More

Read More

Rotary Degassing Machine Manufacturer

In order to remove impurities from the melt, and make better quality metal, one of the most common and effective cleaning methods used by foundries is rotary degassing. With the increase in aluminum castings, foundries have to run the most efficient and cost-effective processes possible, so as to offer price ...

Read More

Read More

Aluminium Degassing Process

The aluminium degassing process can clean metal by removing hydrogen gas, metallurgical impurities. Rotary degassing works on the principle of increasing the surface area of an insert gas exposed to the metal. The larger surface area increases the rate of transfer from metal to the inert gas. The smaller the ...

Read More

Read More

How to Use the Molten Aluminum Filter

The filtration efficiency of the molten aluminum filter closely relates to its correct installation and use. At the same time, it is also necessary to prevent the recontamination phenomenon of the clean liquid aluminum after filtration. How to Use the Molten Aluminum Filter In general, the use of alumina foam ...

Read More

Read More

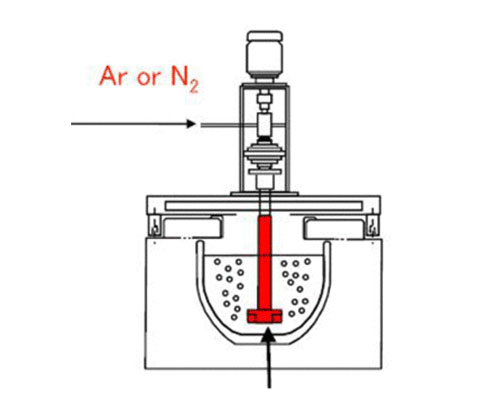

Online Degassing Device

Online degassing device is an advanced metal purification device with advanced heating elements. It is suitable for removing gases and harmful impurities in melton aluminum and aluminum alloy. Online degassing unit adopts advanced high silicon melting technology to get a long service time, degassing rotor, heater protection thimble and thermocouple ...

Read More

Read More

Metal Transfer Runner System

Metal Transfer Runner System is also called Ceramic Launder, Casting Launder. It is a silicic acid fiber product, and mainly suitable for liquid aluminum distribution and transmission. Casting Launder has higher requirements for heat preservation. AdTech casting launder size can be customized according to customer requirements. The Ceramic Launder adopts ...

Read More

Read More

Liquid Aluminum Casting Tube

Adtech company specializes in the development and production of new types of metallurgical materials. AdTech aluminum casting tubes adopt high-silicon melting materials. Liquid aluminum casting tube is also called alumina ceramic tundish nozzle. Aluminum silicate tundish nozzle is suitable for low-pressure castings, it can adjust the flow of molten aluminum ...

Read More

Read More