Aluminum Purification Technology

The use of aluminum alloy castings is increasing, and the requirements for castings are becoming higher and higher. In addition to ensuring chemical composition, mechanical properties and dimensional accuracy, aluminum alloy castings are not allowed to have casting defects such as shrinkage holes, air holes, and slag holes. Aluminum purification ...

Read More

Read More

Molten Aluminum Casting

Aluminum alloy smelting and pouring are the main links in molten aluminum casting production. The strict control of the entire process of melting and pouring plays an important role in molten aluminum casting defects. Since the aluminum melt has a large tendency to absorb hydrogen, the oxidation ability is strong ...

Read More

Read More

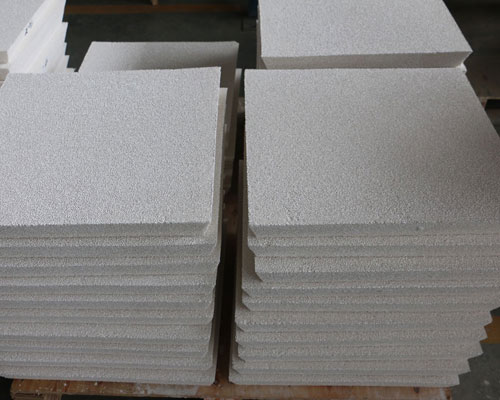

How to Choose Ceramic Foam Filters

The ceramic foam filter can improve the cleanliness of the melton aluminum. AdTech alumina ceramic foam filter can effectively eliminate large inclusions in the molten aluminum, as well as small inclusions of a few microns. The choice of the filter plate is a technical task. And how to choose the ceramic ...

Read More

Read More

Aluminum Casting Process

Aluminum is an active metal element, and aluminum easily oxidizes and absorbs the gas in the aluminum casting process. The aluminum oxidation (Al2O3) has a high melting point (2 050 ° C), the density slightly is greater than liquid aluminum. It is difficult to remove in the suspended liquid aluminum, ...

Read More

Read More

Ceramic Foam Market

Ceramic foam market development began in the 1970s. It is an inorganic non-metallic solid material with many air holes. Ceramic foam uses the hollow structure, surface structure and its own material properties, so as to achieve the physical, chemical and other mechanical properties required by the application. In terms of ...

Read More

Read More

Molten Aluminum Degasser

Molten aluminum degasser can achieve the purpose of purifying the aluminum alloy. With the development of the automotive industry, more and more aluminum alloy castings are used, and the requirements for casting are becoming higher and higher. In addition to ensuring the chemical composition, mechanical properties, and dimensional accuracy. Aluminum ...

Read More

Read More

Tundish Nozzle

Tundish nozzle is also called ceramic tube, alumina tube, casting tube. We produce a very wide range of high-quality Tundish Nozzles. AdTech tundish nozzles are suitable for controlling the flow of molten aluminum. It has a better performance compared to other nozzles. Tundish nozzle has the advantages of heat preservation, ...

Read More

Read More

Aluminum Dross Recycling

Aluminum dross recycling has certain economic value. The worldwide aluminium industry produces nearly five million tonnes of furnace waste each year. Known as dross, aluminum slag is produced in aluminum melting processes. The deslagging flux has the function of removing slag in the high-temperature molten metal. Because scrap aluminum slag ...

Read More

Read More

Riser Sleeve Used in ARC

Riser Sleeve Used in ARC and graphite ring ensure the dimensional accuracy of the Aluminum billet. Riser Sleeve is also called sprue bush, aluminum casting billet mold. To meet the growing demand for aerospace alloy material, Wagstaff developed the ARC mold technology. It solves the challenges inherent to large diameter, ...

Read More

Read More

Boron Nitride Ceramic Material

Boron Nitride Ceramic Material is widely used in machinery, metallurgy, chemical industry, electronics, nuclear energy and aerospace fields. It has excellent performance and great development potential. Boron nitride is a crystal composed of nitrogen atoms and boron atoms. The chemical composition is 43.6% boron and 56.4% nitrogen, and the theoretical ...

Read More

Read More