AdTech degassing equipment has an ultra-long life furnace body using a new high-silicon molten material manufacturing technology. The degassing rotor, heater protection sleeve, and thermocouple protection sleeve are all made of silicon nitride (Si3N4) ceramic manufacturing technology and production Production technology of aluminum products with high added value and high technical performance requirements.

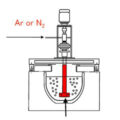

The AdTech on-line degassing equipment produced is installed between the furnace and the casting machine, and its role is to eliminate the hydrogen and other residues contained in the molten aluminum and its alloys that affect its quality and mechanical properties. It has dual functions: processing and heating. Mainly used for melt purification in the production of high-precision aluminum products, such as computer hard disks, color and black and white photocopier drums, micron aluminum foil wool, PS board base for printing, canning materials, aircraft landing gear, jet turbine engine fan blades and many more.

AdTech degassing equipment is mainly divided into several categories: single rotor degassing box, double rotor degassing box, and three rotor degassing box.

Instructions for Using AdTech Online Degassing Equipment

When the oven is finished, the heating element is turned off before the molten aluminum enters the box. When the temperature of the heater is close to that of the molten aluminum, inert gas is introduced into the rotor, and then the molten aluminum is filled into the box.

Check the sealing material at the junction of the inlet and outlet and the runner.

Check the tight plug of the bottom drain port with high-temperature protection.

Check whether the temperature of the molten aluminum in the filling tank is high enough (minimum temperature: 720°C). In order to observe the molten aluminum entering the tank, stop the filling operation at a position about 3 cm away from the bottom of the launder.

The box cover is closed (the box has a slag raking port). The operator must wear a proper protective jacket. When the metal flows into the box, scum is generated, and the slag on the metal surface can be skimmed through the slag raking port.

It is recommended that the temperature rise to above 780 degrees to reproduce, start the temperature holding stage, and close the slagging port.

The heat preservation stage allows the molten aluminum in the casting time to remain in the box at the temperature set by the operator.

No aluminum liquid is processed in this holding stage.

A small amount of inert gas needs to be introduced into the rotor to prevent molten aluminum from entering the rotor and blocking the rotor vents.

After the molten metal stops filling operation, the heater needs to be started immediately, and the heating is controlled according to the metal insulation parameters, which is set by the operator.

By starting the heating system to control the temperature of the molten aluminum, it is necessary to monitor the gas flow rate, the rotor speed increases, and the speed is changed from the holding stage to the set speed in the processing stage, and the inert gas flow into the rotor increases, from the holding stage to the processing stage flow.

The operator sets the temperature of the molten aluminum in the processing stage and heats in this mode to achieve a stable degassing working state.